Oil Furnace Efficiency Test

While oil furnaces often have a design service life exceeding 26 years a unit that age has operational inefficiencies that would justify replacement with more efficient equipment.

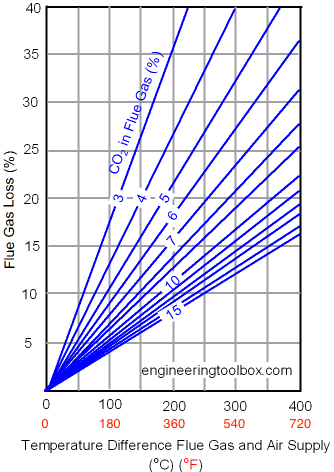

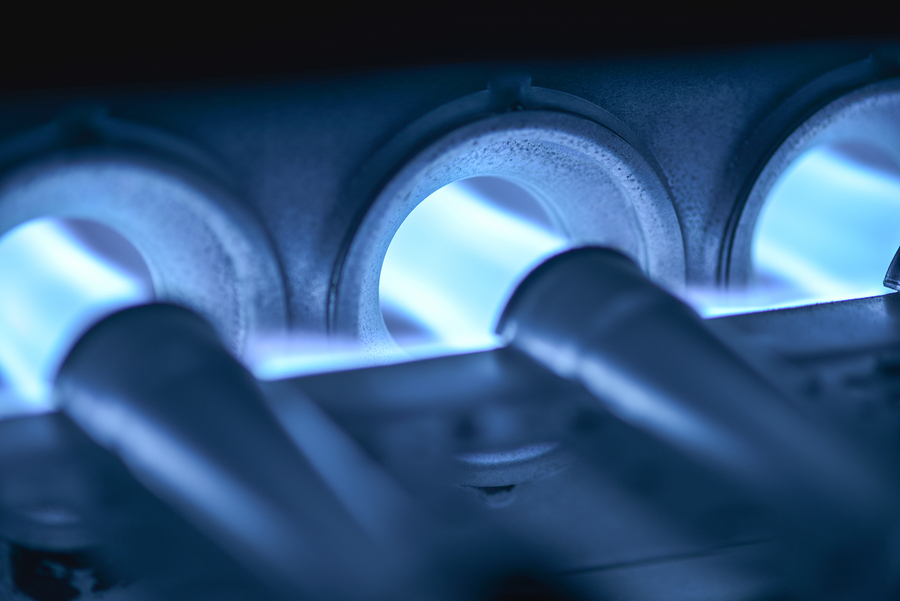

Oil furnace efficiency test. An oil burner flame that. We include charts showing the standard ratios or relations between an oil burner co 2 level measured in. This article explains and illustrates how an oil burner co 2 test is performed a key step in oil burner adjustment. This article explains and illustrates oil burner smoke testing a key step in oil burner adjustment for proper operation.

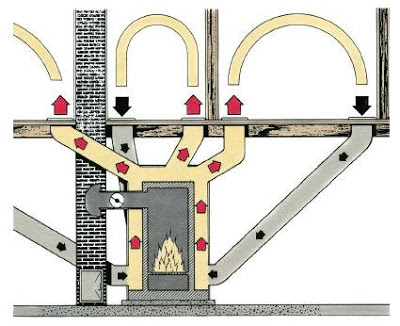

An oil burner flame that is too smoky soots up the heating system leading ultimately to a no heat call and a clogged furnace or boiler or water heater. If your furnace or boiler is old worn out inefficient or significantly oversized the simplest solution is to replace it with a modern. Oil burner carbon dioxide level testing which in turn reflects combustion air temperature adjustment is necessary for safe efficient and reliable oil burner operation. Oil burner smoke test combustion air temperasture adjustment.

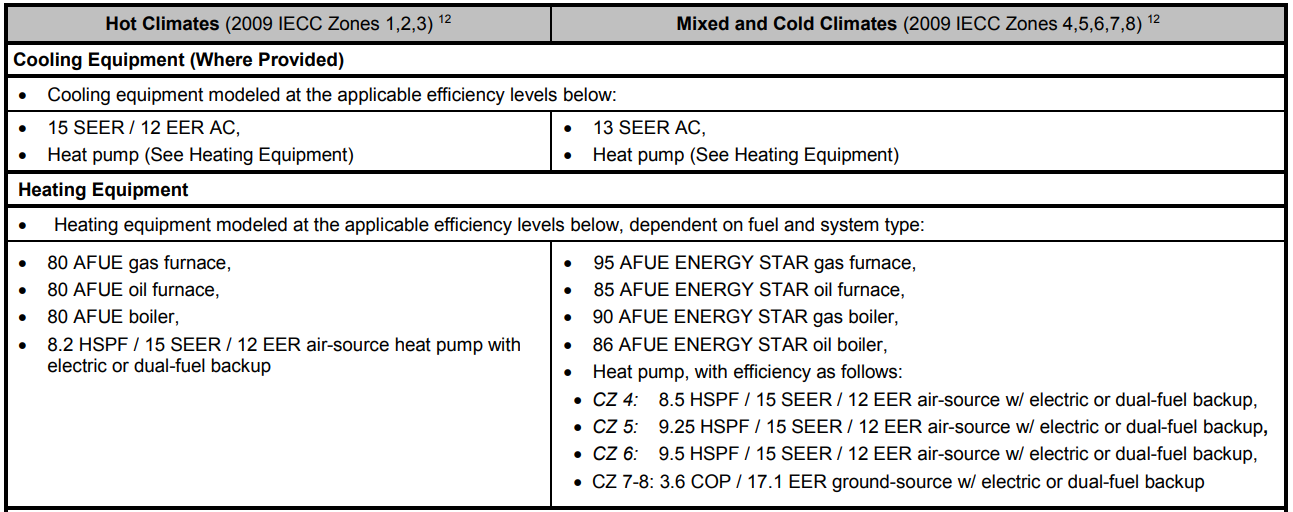

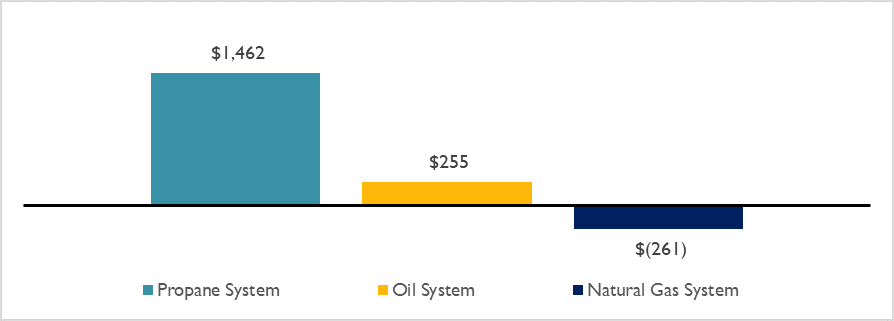

Annual fuel utilization efficiency. Afue is a measure of how efficient the appliance. Although gas furnaces are more efficient than oil furnaces that efficiency comes at a price gas units are typically priced 10 to 25 higher than the same size oil furnace. Lennox gas and oil furnaces are engineered to deliver perfect warmth efficiency and energy savings.

Upgrading your furnace or boiler from 56 to 90 efficiency in an average cold climate house will save 1 5 tons of carbon dioxide emissions each year if you heat with gas or 2 5 tons if you heat with oil. All new furnaces are.