Operation Failed Due To Geometric Condition Sheet Metal

Solidworks operation failed due to geometric condition.

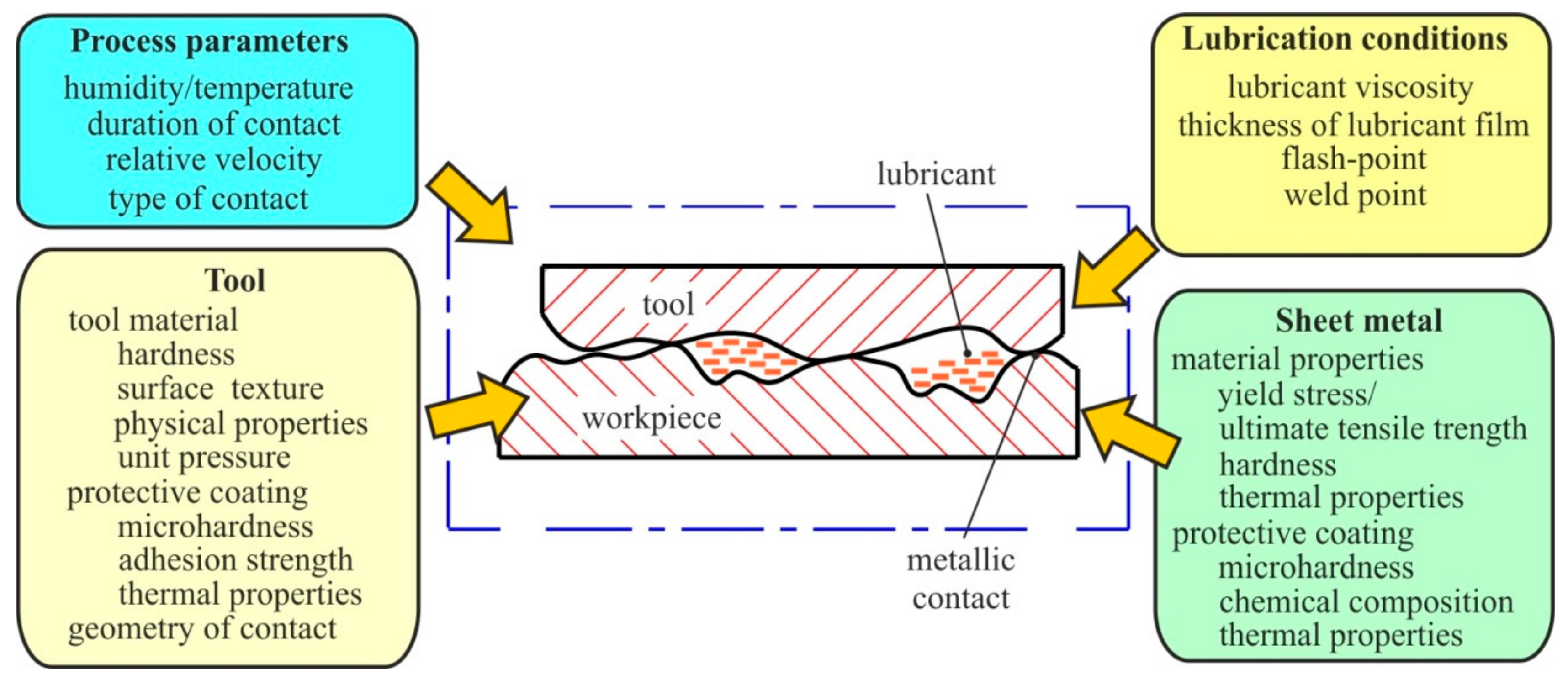

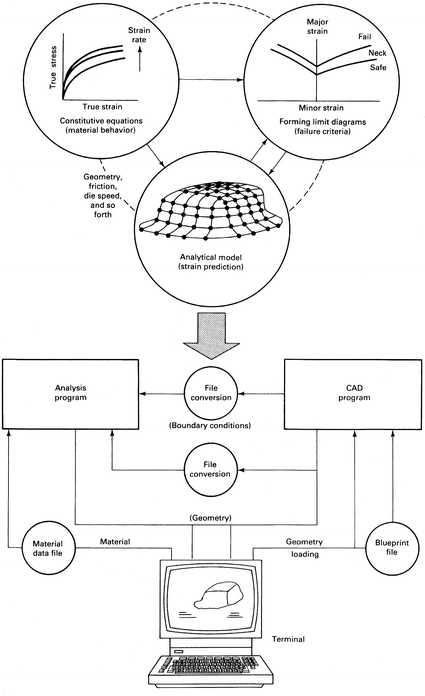

Operation failed due to geometric condition sheet metal. A typical sheet metal bending operation involves mounting a punch punches and mould die on a press which controls relative motions between the punch and die. 2a as governed by the geometry and kinematics of the press and tooling system and the press crankshaft rotational speed. Operation failed due to geometric condition appeng mechanical 21 jan 08 09 45 its hard to tell from that picture really but lets think about this a bit. Regardless your surface has to be completely knitted and often it s best to ensure its boundary completely overlaps the to be cut body.

The mechanical press operated continuously at 32 strokes per minute. Sheet metal operation gives many advantages over forging or casting process which makes it a most versatile operation. Are made by this process. Pantelis karamailis 6 jan 2016 06 03 pm hello i ve been working on the f1 in schools competition.

If there is no fault in the faces prior to the mirror and bad faces after the mirror then we need to look at how we are mirroring or how we are lofting. Like show 0 likes 0. Then placing sheet metal on a die against a auto stopper block or a gauge to position the part. Question asked by austin prater on aug 18 2016 latest reply on aug 19 2016 by brad.

Cutting surface failed due to geometric condition. Punch es and the mould die provide the necessary bending forces or pressures. For some of reason sometimes only one of the two will work for the same operation. There are many others like file cabinets air craft body metal cans metal doors etc.

Will there be more in the future. If the software is smart enough to recognize that an operation won t work because of a geometric condition how about letting me know what the geometric condition is so i can fix it. The metal desk which you used for arrange your books is a sheet metal product. Operation failed due to geometric condition.

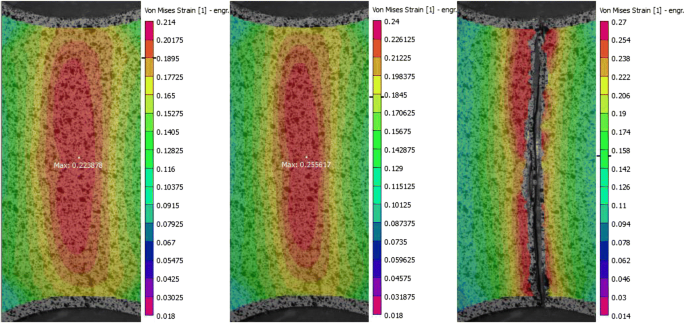

Covid 19 coronavirus disease. At this press rate the punch speed is approximately 300 mm s at the beginning of the forming operation and reduces to 0 mm s at the end of the 40 mm forming stroke see fig. Operation failed due to geometric condition.