Operational Manual For Power Driven Sheet Metal Bending Machine

Modelling of metal sheet bending machine.

Operational manual for power driven sheet metal bending machine. Forces analysis of metal sheet by analytical method. Workpieces can be bent after one feeding besides extensive emendation is also available. Before discussing about bending process and its types first you should learn about basic terminologies used in bending. Considering manual operation is replaced by power operated devices it also gives information about limitation of manually operated sheet bending machine and power operated sheet bending machine.

Mac afric sheet metal folding machine with foot control. Sheet metal is used in the. Bending brakes mac afric 900 mm sheet metal bending brake. Engineering equipment mac afric 1 3 m slip roller machine.

Main applications and usage scope. There are highly sophisticated models used in industries for bulk processes as well as those that are used in low production processes in small work shops or tool rooms on a work site. Simulation of sheet metal bending machine with different materials. Many products like automobile components and its body home appliance paper clip metal doors etc.

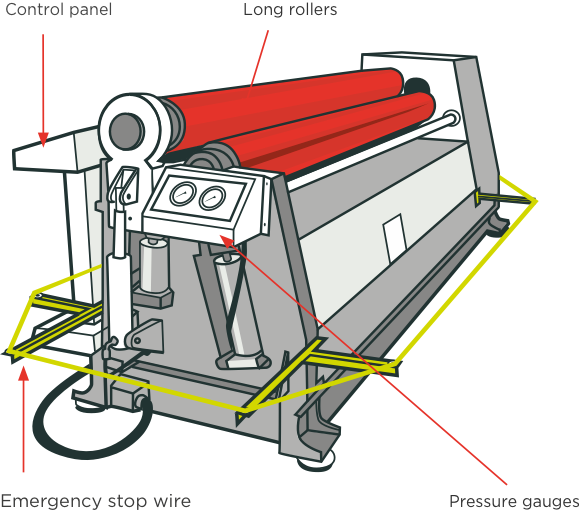

The safety guide introduces safeguarding measures that can be retrofitted to your shearing machine. W24s profile bending machine consists of machine body side roller part support roller part electrical system and hydraulic system. Some of the popular kinds. Various types of sheet metal machines are used in different applications including power press machines bending machine hydraulic press arbour press swaging sheet metal machine imported sheet metal machine for cut press bend and form sheet metals into different shapes and sizes by bhavya machine tools ahmedabad india.

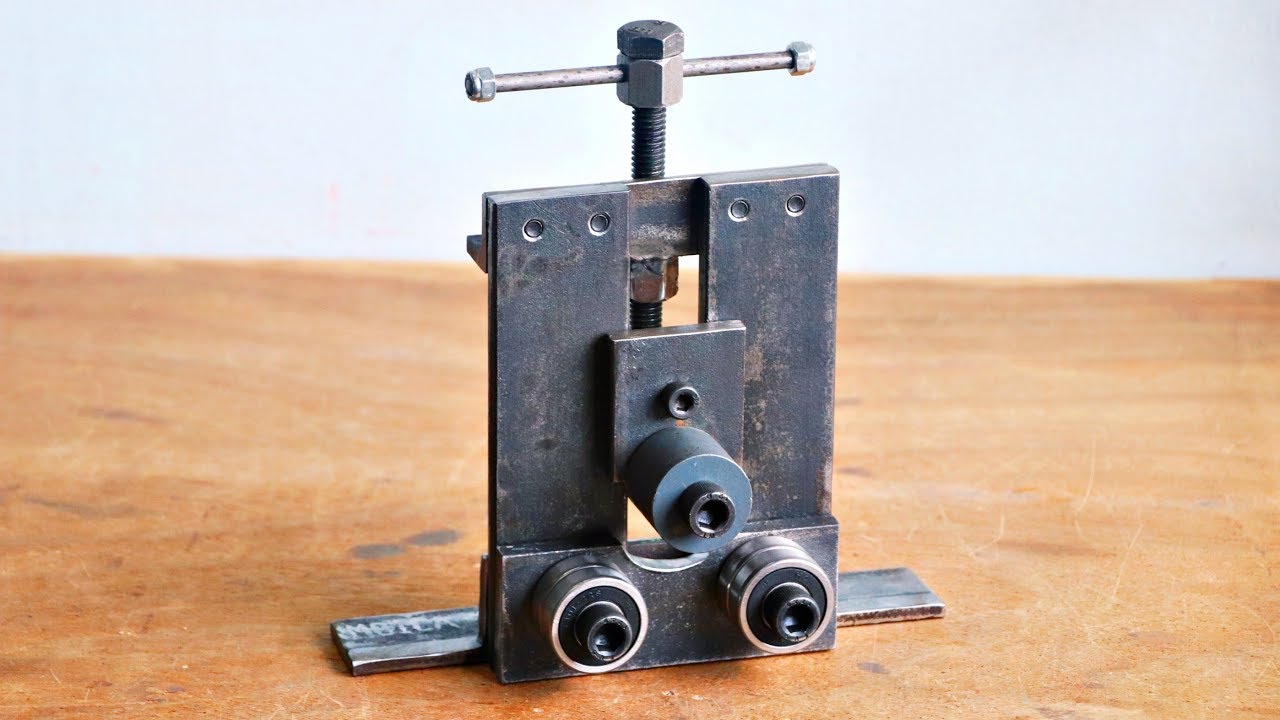

The paper deals with manufacturing or bending of sheet metal by using power operated sheet bending machine. Types of sheet bending machines. Bending is a most common sheet metal forming operation. Bending force analysis of metals sheet during bending operation by software approach.

Request a quote. Shape bending cylindrical automatic hoppers frame fabrication production introduction sheet metal fabrication plays an important role in the metal manufacturing world. Currently being used at company x engineering is a manual bending machine with a single operation hence this design will help to increase the number of metals being bent an increase in the efficiency and production. Are shaped by bending process.

Fully recognize hazards associated with machine installation worksheet and blade setup machine operation inspection cleaning and maintenance and other tasks. The machine body is a whole welded structure the left and right running arms are installed in machine body which droved by two hydraulic pumps and do arc up and down movements. Power operated sheet bending machine.