Osb Vs Cdx Roof

Osb does not do well when it gets wet.

Osb vs cdx roof. The roof deck is the surface underneath your roof and roofing underlayment. Oriented strand board osb combines wood chips glue and resin into the shape of a sheet of plywood and bakes them together. When you count sub floors roofs and wall sheathing osb claims about 70 of the wood sheathing market in north america over plywood. Cdx is veneer plywood.

How do cdx and osb differ in performance. It is also used for roof sheathing. Because of this manufacturing process osb is at least half the cost of cdx plywood. My personal opinion is that osb performs well on the wall and floor but stick to cdx plywood on the roof.

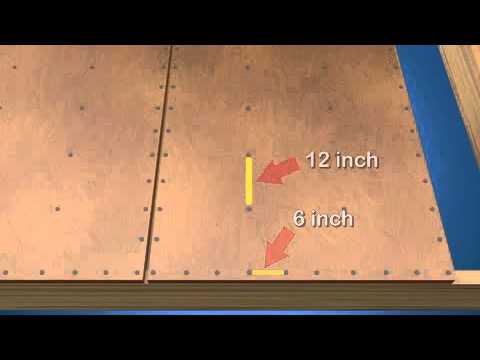

We have used osb for some time now we use 5 8 on the roof 7 16 on the sidewalls all with plywood clips for strength and proper exspansion gaps however 3 4 t g ulc or cdx for floors stands up to the weather while building. Over the years i have seen claims for plywood decking delaminating which can cause squeeks and knocks between the ply s. Although osb typically offers a higher shear rating which adds rigidity to your structure. It is usually made of 4 by 8 sheets that should be 1 2 thick.

Odds are that if you pass a housing development of wood framed houses it will have osb oriented strand board as exterior sheathing. My personal opinion is that osb performs well on the wall and floor but stick to cdx plywood on the roof. New homes will usually see a few rainfalls before a roof is on and as. It is made of multiple layers of thinly cut solid sheets of wood that are pressed together.

Most construction sites will consider the use of either osb or plywood for the roof. Far too often i see osb sag between the trusses making your roof look wavy. Osb is a cheap imitation of cdx. Cdx plywood is a construction grade type of plywood that is designed for exposure to the elements.

Each of these materials has its own unique properties and qualities and so each is used in specific applications. It is often less expensive than cdx plywood because this manufacturing process doesn t require the same costly veneers found on the front and back of cdx plywood. Far too often i see osb sag between the trusses making your roof look wavy. Cdx is best for sub flooring.

Osb is made by combining glue resin and wood chips and pressing them into the shape of a plywood sheet then baking everything together. Although osb typically offers a higher shear rating which adds rigidity to your structure. It can withstand moisture for a brief period of time but may become warped and delaminated with consistent exposure to the elements. It is made of wood chips and glue.

Compared to cdx oriented strand board osb is made very differently.